Solvers help you monitor quality, apply SPC, manage equipment, and ensure traceability.

Solver: Supplier Deviation Management

Enhance engagement and collaboration in identifying and resolving upstream quality issues, boosting operational efficiency and fostering stronger supplier relationships.

Module: Supplier Quality

How can we improve the management and resolution of deviations in incoming goods?

You can’t maintain operational efficiency - or build strong supplier partnerships - without a structured approach to managing and resolving deviations.

Diagnostic questions

How well are you managing supplier-related quality deviations?

- Have deviations in incoming goods gone unaddressed?

- Have ongoing quality issues led to strained relationships with suppliers?

- Are there recurring deviations that should have been addressed by supplier CAPAs?

- Can you track the impact—such as production delays, waste and rework—of supplier deviations on your operations?

Top 4 priorities

You need the AlisQI Supplier Deviation Management Solver to:

- Implement a clear process for documenting and tracking quality issues in incoming goods.

- Collaborate with suppliers to define corrective actions and establish realistic timelines for resolution.

- Ensure the effectiveness of supplier CAPAs in preventing future deviations.

- Prioritize interventions and strengthen accountability by linking deviations to their operational impact.

TIP Effective impact analysis drives urgency and focus. To base interventions on their financial impact, include your supplier-related quality defects in your Total Cost of Quality reports.

Top capability boosters

You’ll achieve more, faster, with the

You’ll achieve more, faster, with the

AlisQI Supplier Deviation Management Solver because you can:

- Streamline and automate documentation for incoming goods.

- Collaborate with suppliers on CAPA workflows, and create alignment on actions and timelines.

- Monitor progress on corrective actions with dashboards and automated alerts.

- Focus improvement efforts based on their operational impact.

- Generate audit-ready reports—on supplier deviations, corrective actions and outcomes—that demonstrate compliance and transparency.

Key application features

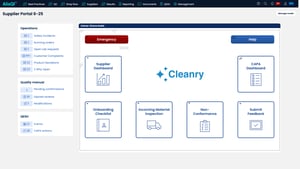

Supplier portal

Collaborate seamlessly with suppliers through AlisQI’s Supplier Portal. Share specifications, track quality issues, and exchange documents in one secure, centralized platform.

Workflow management

Orchestrate your quality processes with AlisQI’s Workflow Management. Define roles, automate approvals, and ensure timely follow-up—so nothing falls through the cracks.