Solvers help you monitor quality, apply SPC, manage equipment, and ensure traceability.

Solver: Incoming Goods Inspection

When your internal quality management is on par, your upstream quality might very well become the weakest link. Make sure you validate incoming goods before you process them.

Module: Supplier Quality

How can we ensure the quality of incoming raw materials?

‘Garbage’ in—increases the likelihood of—‘garbage’ out.

Diagnostic questions

How effective is your inspection of incoming goods?

- Have undetected deviations led to waste and rework?

- Have you faced avoidable quality issues because delivery documentation wasn’t properly reviewed?

- Have nonconformances been missed because COAs weren’t processed systematically?

- Has production been held up because quality results were miscommunicated or not communicated in time?

Top 5 priorities

You need the AlisQI Incoming Goods Inspection Solver to:

- Ensure consistent inspections of all critical raw materials.

- Alert relevant personnel to deviations in incoming goods.

- Process delivery documentation efficiently to confirm that the correct materials have arrived, under the correct conditions.

- Improve traceability, compliance and root cause analysis by

- extracting quality results from COAs

- storing them in a centralized system, and

- linking them to their corresponding batches.

- Create data-driven supplier scorecards by connecting incoming goods inspections with supplier evaluations.

Top capability boosters

You’ll achieve more, faster, with the

You’ll achieve more, faster, with the

AlisQI Incoming Goods Inspection Solver because you can:

- Automatically trigger quality inspections from your ERP’s goods receipt process. (After inspection, lot availability is automatically reflected in your ERP.)

- Automatically alert stakeholders to quality issues in incoming goods.

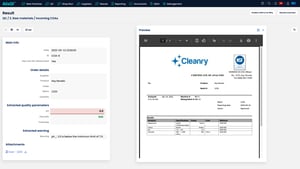

- Automate the extraction, validation and analysis of quality data from COAs.

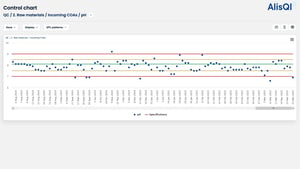

- TIP This not only saves time and reduces errors - it also enables you to detect trends and anticipate nonconformance.

Key application features

PDF COA Data extraction

Automatically extract key data from PDF Certificates of Analysis. AlisQI reads and processes supplier COAs to eliminate manual entry, reduce errors, and accelerate incoming goods inspection.

Specification checking

Ensure product quality with automated Specification Checking. AlisQI instantly validates incoming data against predefined specs - highlighting deviations and triggering workflows when action is needed.

Form builder to create control plans

Design and manage control plans with ease using AlisQI’s no-code Form Builder. Capture critical process parameters, define checkpoints, and standardize quality controls - tailored to your operations.