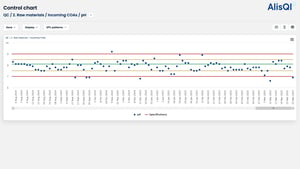

Solvers help you monitor quality, apply SPC, manage equipment, and ensure traceability.

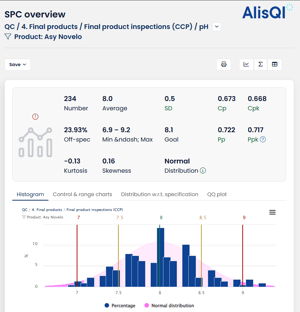

Monitor quality in real time with automated SPC. Instantly detect trends and deviations, reduce manual checks, and ensure consistent, data-driven process control.