Statistical Process Control (SPC) plays an invaluable role in Quality Control, ensuring manufacturers that production processes operate efficiently. However, more often than not, implementing SPC has quality managers digging through endless Excel sheets. And, when there’s lots of data and lots of variation, it can be a tedious task to analyze statistics and react in a timely manner.

As technology advances, making production and quality processes smart, it has become much easier to turn data into insights. We’re here to help you understand how to gain the upper hand on Statistical Process Control while boosting quality and cutting back on costs.

Statistical Process Control: the path to insight and stability

Statistical Process Control (SPC) stands for a set of statistical tools that use Quality Control data to identify trends and patterns. Simply put – SPC helps plant and operations managers to better understand processes by:

- monitoring the data of production

- reducing product variation and sub-standard output

- predicting how the process will behave over time

- identifying areas of improvement

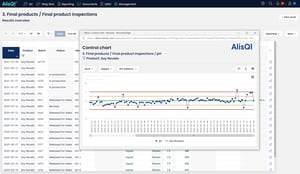

Several SPC tools help visualize the data collected. The most widely used are control charts. These pinpoint variations and teach us about capability and stability in process control.

Statistical Process Control: then versus now

Traditionally, all data used for process control was organized and analyzed in Excel sheets. Many organizations still only use this old-school system. But, when your quality automation tool is a spreadsheet application from the ’80s, you can expect that turning large amounts of data into valuable insight is as time-consuming as it is outdated.

Luckily nowadays, Statistical Process Control doesn’t have to be a pain. The quality intelligence software from AlisQI spares you the trouble of going through Excel sheets, making SPC smart and user-friendly. The fast yet accurate automated system analyzes data, creates control charts, spots anything outside the specs, and sends alerts about the smallest shifts in quality. With real-time, relevant information, it’s much easier to be on top of things and ensure stability.

One manufacturing company that chose AlisQI as their main platform for SPC is Allnex. With 500 products, large amounts of data, and lots of variations, controlling production processes posed a real challenge. Shifting to an automated SPC translated into instant insight and timely alerts about even the smallest deviations.

The benefits of automated Statistical Process Control

Manufacturing companies use SPC to understand what impacts their output and how they could improve quality. In many cases, quality managers use endless Excel sheets to analyze data and compare specifications manually. This is not only time consuming but also prone to error.

On the other hand, an automated SPC processes data and turns it into quality trends. With the AlisQI software, you can expect accurate analytics, meaningful insights and trigger alerts that help you take charge. Better information also means more chances to focus on optimizing processes.

In the case of Allnex, the Quality Manager of the company declared ”We now have an accurate and real-time control system. A problematic product can be accurately followed and safeguarded with SPC”.

An automated solution doesn’t only benefit the quality team. Finance managers can also enjoy these benefits:

- Lower costs. Not being able to prevent product deviations can be rather expensive. Even more so when deviations disrupt the chain of production. Moving to a smart platform for SPC means anticipating issues rather than reacting to them.

- Reducing waste. SPC reduces the chance that the product will need to be scrapped or reworked. Our automated quality management solution reduces waste by 15% and saves up to 20% on the time required to manufacture the product.

AlisQI - your platform for Statistical Process Control

Our software is easy to implement – so easy in fact that you can do it yourself. Moreover, choosing AlisQI as your main platform for SPC, you don’t need to be a statistician to understand the data. The system helps with relevant information and easy-to-follow instructions sent to your dashboard.

Additionally, we offer:

- Free demo. A demo gives you an overview of AlisQI’s functionality, an impression of its flexibility and ease of use, explaining further how your factory can benefit.

- ROI calculator. Guarantees a good investment by showing you the savings our software yields for you.

- Help Center. A support platform with helpful articles that assists you with every step of your quality management journey.

Should there still be any unanswered questions, do not hesitate to contact us. In the meantime, visit our blog to read more about Quality Control, Document Management, QESH Management and many other useful topics.

Five SPC mistakes that you do not need to make...

Others did that for you…